Learning outcomes

This assignment is structured that students show evidence for partial fulfilment of the following module learning outcomes:

[L01] Structured and informed design and development of engineering systems through the application of scientific principles and methodology to a variety of systems

[L02] Apply mathematical and engineering principles as either a part of the whole of the analysis and evaluation of the performance of a variety of engineering systems and processes quantifying the limitations of the modelling

[L03] Apply a systems approach to engineering problems to classify, analyse and evaluate the performance of systems and components through the use of modelling techniques

Do You Need Assignment of This Question

Background

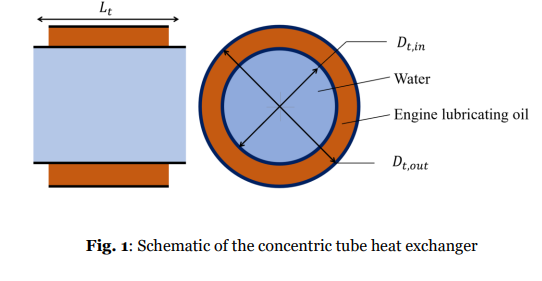

You have recently joined the research department of an engineering company that has been contracted to design and evaluate the heat exchanger system for cooling the lubricating oil for an industrial gas turbine engine bearing. The ball bearings manufacturer indicated that the lubricating engine oil is to be delivered between 55oC and 65oC, inclusive for optimal performance. The customer has requested that you design a simple concentric-tube heat exchanger. Water flows through the inner tube and the lubricating oil flows in the outer annulus. They want to know if you have other suggestions, but mainly want a detailed thermal design and evaluation of your simple concentric-tube design using both analytical and numerical techniques. The industrial customer has given some restrictions that you must also keep to1.

You received a copy of the hand-over note from Joe Bloggs who was originally working on the project before you. Joe recommended (without any evidence or science, perhaps by guessing) that a tube length, 𝐿𝑡, of 150m will be required to achieve this.

Buy Answer of This Assessment & Raise Your Grades

In this work, you are to critically analyse and evaluate the performance of your design based on the customer’s request and use supporting literature where applicable in your recommendations. Your manager would like to know your view on Joe’s recommendation.

– The flow rate of the cooling water, 𝑚̇ 𝑤 [kg/s] where 0.15 ≤ 𝑚̇ 𝑤 ≤ 0.25

– The flow rate of the lubricating oil, 𝑚̇ 𝑜 [kg/s] where 0.10 ≤ 𝑚̇ 𝑜 ≤ 0.15

– Inlet temperature of lubricating oil, 𝑇𝑜,𝑖𝑛 [oC] where 95 ≤ 𝑇𝑜,𝑖𝑛 ≤ 120

– Inlet temperature of cooling water, 𝑇𝑤,𝑖𝑛 [oC] where 25 ≤ 𝑇𝑤,𝑖𝑛 ≤ 35

– The inner tube diameter is 𝐷𝑡,𝑖𝑛 [mm] where 25 ≤ 𝐷𝑡,𝑖𝑛 ≤ 35

– The outer tube diameter is 𝐷𝑡,𝑜𝑢𝑡 [mm] where 45 ≤ 𝐷𝑡,𝑜𝑢𝑡 ≤ 55

– Use copper in the inner tube with a thickness of 5mm in your CFD analysis. You can neglect this thickness and foul your analytical calculations.

– Assume constant properties; See Table 1 for oil properties.

– Make and state other reasonable assumptions.

– Carry out a CFD analysis on a section of the simple design. Use the analytical method to verify your CFD.

– Using CFD techniques, how can this design be improved?